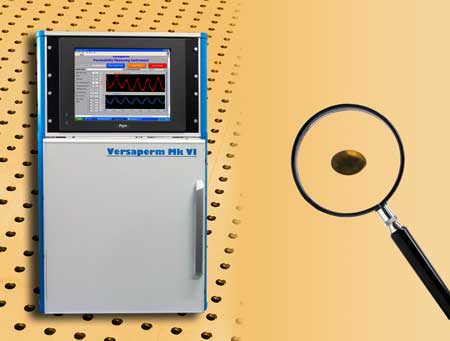

Pinholes in packaging films and foils

For both loose and pre-packed produce

Click

on the image to download a print quality scan

Pinholes can be a major headache in high barrier packaging for medical, industrial and food packaging. Films pinhole easily during manufacture and even sub-mm gauges of aluminium foil invariably contain pinholes. This allows moisture, oxygen and CO2 (etc) to enter or exit the package degrading its contents, reducing quality and reducing shelf life.

The solution to boosting shelf life and quality lies in the nearness of the match between the respiration rates, including pinholes, and the packaging’s oxygen, carbon dioxide and water vapour permeabilities. Versaperm’s multi-gas option can determine these to a high degree of accuracy under a wide range of environmental options. The equipment can also be used to determine the characteristics of the pinholes.

Several of these environmental factors affect the barrier properties of a packaging material including temperature and relative humidity. Vapour permeability varies dramatically depending on the gas or vapour under question, for example the permeation rates for water vapour, oxygen and CO2 can be hundreds or even thousands of times different.

ENDS

Please send

any sales enquiries to Christopher Roberts, Versaperm Limited ,

10 Rawcliffe House, Howarth Road, Maidenhead, Berkshire, SL6 1AP, UK, Tel: +44 (0) 1628 777668,

e.mail info@versaperm.co.uk

Web http://www.versaperm.co.uk

For further

Press Information please contact Gerry Palmer @ the Palmer & Rose

Partnership. Tel +44 (0) 1494 637499, e.mail gerry@palmer-rose.co.uk.

|